.jpg?x-oss-process=image/resize,w_100/quality,q_100)

CHQ Wire(Cold Heading Quality Wire)

Application:Automobile manufacturing, machinery, precision electronics, rail transportation, aviation, construction and other fields.

Materials making coupling parts such as bolts, nuts and screws for use in automobiles, electronic products, construction, etc.

|

Steel Grade |

Symbol |

Diameter |

|

|

Cold Heading Steel |

SWCH6A、SWCH8A、SWCH10A、SWCH15A、SWCH16、SWCH18A、SWCH22A |

|

2.00~42.00mm |

|

SWCH25K、SWCH35K、SWCH38K、SWCH40K、SWCH45K、SWCH50K |

HD |

2.00~42.00mm |

|

|

10B16、10B21、10B28、10B30、10B33 |

SA |

2.00~42.00mm |

|

|

SCM435、SCM440、SCr440 |

SAF |

2.00~42.00mm |

|

|

20MnTiB、20MnVB、20CrMnTi |

SAIP |

2.00~42.00mm |

|

|

50BV30、32CrB4、30CrMnSi |

PASAF |

2.00~42.00mm |

|

|

20Cr、17Cr3、16MnCr5 |

PASAIP |

2.00~42.00mm |

|

|

45Mn2 |

PSASAF |

2.00~42.00mm |

|

|

ML08Al、ML10Al |

|

2.00~42.00mm |

|

|

Bearing Steel |

SUJ2、GCr15、100Cr6 |

PSASAIP |

2.00~42.00mm |

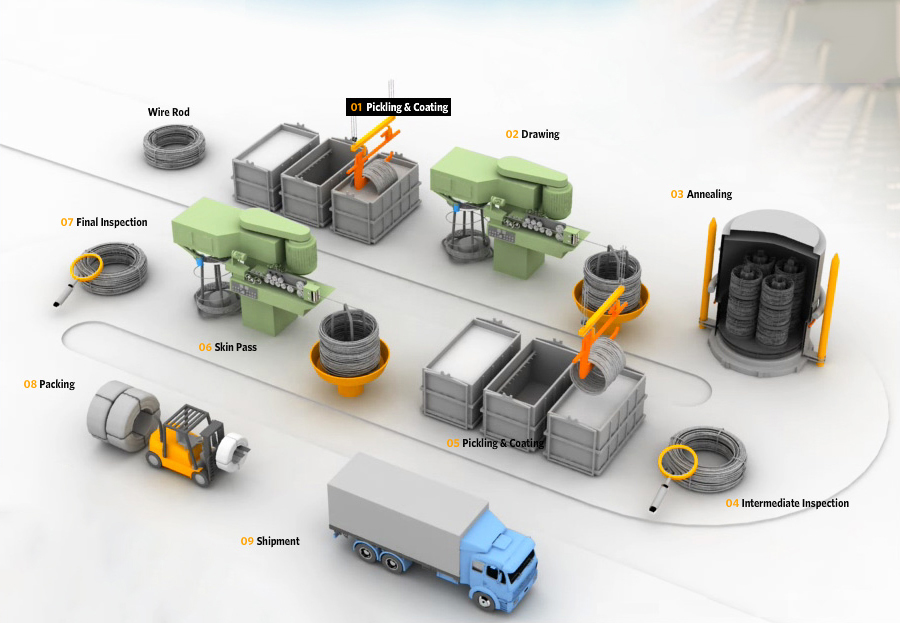

APPLICATION,MATERIAL AND MANUFACTURING PROCESS:

|

Application |

Material |

Manufacturing Process |

|

Ball & Roller Bearing |

SUJ2 |

PASAIP |

|

Ball Housing |

SWRCH45K |

PSASAIP |

|

Ball stud |

SCM415H~440 |

PASAIP |

|

Boxer Wrench |

SCM415H |

PASAIP |

|

Chain Pin |

SCM415H~435 |

PASAIP |

|

Cylinder Head Bolt |

SCM435H |

PASAIP |

|

Electronic nut |

SWRCH18A~22A |

SAIP |

|

Armature Shaft |

SWRCH45K |

SAIP |

|

Flange Bolt & Nut |

SWRCH35K~45K、SCM435、SWRCH10A |

SAIP/PSASAIP、PASAIP、HD |

|

Hexagonal bolts |

SCM435、SWRCH45K |

PASAIP、SAIP |

|

Hub Bolt &Nut |

ML20MnTiB、SCM435 |

SAIP、PASAIP |

|

Lead Wire |

SWRCH6A~8A |

HD |

|

Piston Pin |

SCM415H~435H |

PASAIP |

|

Screw & Nut |

SWRCH6A~10A |

HD、SAIP |

|

Starter Motor Parts |

10B21、SWRCH45K |

SAIP、SAIP |

|

Tire Rod Pin |

SWRCH45K |

SAIP |

|

Tire Spoke |

SCM435 |

PASAIP |

|

Wheel Nut Wrench |

SWRCH45K |

SAIP |

|

Wrench Bolt |

SWRCH45K |

SAIP |

|

Hex head bolt |

SWRCH10A、SWRCH25K |

HD、SAIP |

|

Spark plug |

SWRCH8A~10A |

SAIP |

|

Cold rivet used in the train |

45Mn2 |

PASAIP |

|

Advanced hand implement |

50BV30 |

SAIP |

|

Flange Bolt &Nut |

SCM440 |

PASAIP |

|

Bolt used in heavy truck |

SCr440 |

PASAIP |

|

Bolt used in engine connecting-rod |

30CrMnSiA |

PASAIP |

|

Start Motor Parts |

10B30 |

SAIP |

CLASSIFIED BY CHEMICAL COMPOSITION:

|

Brand |

Chemical Composition(%) |

||||||||||

|

C |

Si |

Mn |

P,≤ |

S,≤ |

Alt,≥ |

Ti |

B |

Cr |

Mo |

V |

|

|

SWCH6A |

≤0.08 |

≤0.10 |

≤0.60 |

0.020 |

0.020 |

0.020 |

|

|

|

|

|

|

SWCH8A |

≤0.10 |

≤0.10 |

≤0.60 |

0.020 |

0.020 |

0.020 |

|

|

|

|

|

|

SWCH10A |

0.08~0.13 |

≤0.10 |

0.30~0.60 |

0.020 |

0.020 |

0.020 |

|

|

|

|

|

|

SWCH15A |

0.13~0.18 |

≤0.10 |

0.30~0.60 |

0.020 |

0.020 |

0.020 |

|

|

|

|

|

|

SWCH16A |

0.13~0.18 |

≤0.10 |

0.60~0.90 |

0.020 |

0.020 |

0.020 |

|

|

|

|

|

|

SWCH18A |

0.15~0.20 |

≤0.10 |

0.60~0.90 |

0.020 |

0.020 |

0.020 |

|

|

|

|

|

|

SWCH22A |

0.18~0.23 |

≤0.10 |

0.70~1.00 |

0.020 |

0.020 |

0.020 |

|

|

|

|

|

|

SWCH35K |

0.32~0.38 |

0.10~0.35 |

0.60~0.90 |

0.020 |

0.020 |

|

|

|

|

|

|

|

SWCH38K |

0.35~0.41 |

0.10~0.35 |

0.60~0.90 |

0.020 |

0.020 |

|

|

|

|

|

|

|

SWCH40K |

0.37~0.43 |

0.10~0.35 |

0.60~0.90 |

0.020 |

0.020 |

|

|

|

|

|

|

|

SWCH45K |

0.42~0.48 |

0.10~0.35 |

0.60~0.90 |

0.020 |

0.020 |

|

|

|

|

|

|

|

SWCH50K |

0.47~0.53 |

0.10~0.35 |

0.60~0.90 |

0.020 |

0.020 |

|

|

|

|

|

|

|

ML08Al |

0.05~0.10 |

≤0.10 |

0.30~0.60 |

0.035 |

0.035 |

0.020 |

|

|

|

|

|

|

ML10AI |

0.08~0.13 |

≤0.10 |

0.30~0.60 |

0.035 |

0.035 |

0.020 |

|

|

|

|

|

|

10B16 |

0.13~0.18 |

≤0.10 |

0.80~1.10 |

0.020 |

0.020 |

|

|

0.0005~0.0030 |

|

|

|

|

10B21 |

0.18~0.23 |

≤0.10 |

0.70~1.00 |

0.020 |

0.020 |

|

|

≥0.0008 |

|

|

|

|

10B28 |

0.26~0.32 |

≤0.40 |

0.70~1.00 |

0.030 |

0.030 |

|

|

0.0008~0.0050 |

|

|

|

|

10B30 |

0.28~0.34 |

≤0.30 |

0.80~1.00 |

0.020 |

0.020 |

|

|

0.0005~0.0030 |

|

|

|

|

SCr440 |

0.38~0.43 |

0.15~0.35 |

0.60~0.90 |

0.020 |

0.020 |

|

|

|

0.90~1.20 |

|

|

|

SCM435 |

0.33~0.38 |

0.15~0.35 |

0.60~0.90 |

0.020 |

0.020 |

|

|

|

0.90~1.20 |

0.15~0.30 |

|

|

SCM440 |

0.38~0.43 |

0.15~0.30 |

0.60~090 |

0.020 |

0.020 |

|

|

|

0.90~1.20 |

0.15~0.30 |

|

|

ML20MnTiB |

0.19~0.24 |

≤0.30 |

1.30~1.60 |

0.020 |

0.020 |

0.020 |

0.04~0.10 |

0.0005~0.0035 |

|

|

|

|

20CrMnTi |

0.17~0.23 |

0.17~0.37 |

0.80~1.10 |

0.020 |

0.020 |

|

0.04~0.10 |

|

1.00~1.30 |

|

|

|

ML20MnVB |

0.19~0.24 |

≤0.30 |

1.20~1.60 |

0.020 |

0.020 |

0.020 |

|

0.0005~0.0035 |

|

|

0.07~0.12 |

|

ML15MnVB |

0.14~0.19 |

≤0.30 |

1.20~1.60 |

0.020 |

0.020 |

0.020 |

|

0.0005~0.0035 |

|

|

0.07~0.12 |

|

50BV30 |

0.27~0.33 |

≤0.10 |

0.70~1.00 |

0.020 |

0.020 |

|

|

≥0.0005 |

0.30~0.50 |

|

0.10~0.15 |

|

32CrB4 |

0.30~0.34 |

≤0.30 |

0.60~0.90 |

0.020 |

0.020 |

|

|

0.0008~0.0050 |

0.90~0.20 |

|

|

|

20Cr |

0.17~0.21 |

0.17~0.37 |

0.50~0.80 |

0.020 |

0.020 |

|

|

|

0.70~0.10 |

≤0.15 |

|

|

17Cr3 |

0.16~0.21 |

0.15~0.30 |

0.60~0.90 |

0.020 |

0.020 |

|

|

|

0.70~0.10 |

|

|

|

16MnCr5 |

0.14~0.19 |

≤0.40 |

1.00~1.30 |

0.020 |

0.020 |

|

|

|

0.80~1.10 |

|

|

|

45Mn2 |

0.42~0.49 |

0.17~0.37 |

1.40~1.80 |

0.030 |

0.030 |

|

|

|

|

|

|

Materials making coupling parts such as bolts, nuts and screws for use in automobiles, electronic products, construction, etc.

1.Pickling&Coating

Pickling: in this process, acid is used to remove high temperature oxidized scales that are created on the metal surface during wire rolling, as well as rust and attached impurities that are created while the material is kept.

Coating: in this process, a synovial layer on the metal surface is formed to prevent direct contact between the tool and the material in the drawing process and cold forging process with the goal of workability improvement and decarburization prevention during annealing.

2.Drawing

In this process, the pickled and coated material is passed through dies to draw wire with required wire diameters. In this process, the pearlite structure is segmented through cold processing, to facilitate spheroidizing during annealing and to adjust wire drawing reduction ratios with the goal of meeting the required machine properties after wire drawing.

3.Annealing

In this process, pearlite, the raw material (wire rod) structure, is converted into a stable spherical carbide with the goal of lowering its strengths and expanding its ductility, thus improving transmutability during cold forging.

4.Intermediate Inspection

In this process, the produced product is being inspected to assess whether it is ready for post-processes.

5.Pickling&Coating

Pickling: in this process, acid is used to remove high temperature oxidized scales that are created on the metal surface during wire rolling, as well as rust and attached impurities that are created while the material is kept.

Coating: in this process, a synovial layer on the metal surface is formed to prevent direct contact between the tool and the material in the drawing process and cold forging process with the goal of workability improvement and decarburization prevention during annealing.

6.Skin Pass

In this process, the pickled and coated material is passed through dies to draw wire with required wire diameters. The precise wire diameter quality is secured, wires curved during surface refinement treatment and annealing are straightened and wires are given appropriate strength with the goal of producing a finished product in this process.

7.Final Inspection

In this process, a finished product is inspected to assess whether the product meets required specifications.

8.Packing

In this process, the product is packed to prevent damaging, binded by unit according to the request specifications and standard packaging method prior to shipping.

9.Shipment

Other Technical Details

Dimensional range:Standard dimensions are 0.50 mm - 49.0 mm

Diameter tolerances:Tightest diameter tolerances EN 10278 (h8, h9, h10, h11)

Surface:

· Phosphate-free

· Phosphated

· Finally phosphate coated, soap or lime coating

· Bright drawn

With our cold heading wire we are a reliable partner to the automotive supply industry, the mechanical engineering and metal construction industries.

In addition, we also have other cold heading steel wires, such as SWCH6A, SWCH8A, SWCH10A, SWCH15A, SWCH16, SWCH18A, SWCH22A, SWCH25K, SWCH35K, SWCH38K, SWCH40K, SWCH45K, SWCH50K, 10B16, 10B21, 10B28, 10B30, 10B33, SCM435, SCM440, SCr440, 20MnTiB, 20MnVB, 20CrMnTi, 50BV30, 32CrB4, 30CrMnSi, 20Cr, 17Cr3, 16MnCr5, 45Mn2, ML08Al, ML10Al, SUJ2, GCr15, 100Cr6, 60Si2MnA, 60Si2CrA, B55SiCr, 54SiCr6, 55SiCr, B55SiCrV, 50CrVA, 60Si2CrVAT, 60Si2CrVA, B65SiCrV, 55Cr3, 10B33, 10B35, 10B38, 10B21M, 10B23M, 10B33M, 19MnB4, 20MnB4, 22MnB4, 23MnB4, 30MnB4, 36MnB4, 15B25, 15B25M, 17B2, 28B2, 28B2M, 35B2, 38B2, 37MnB5, 20CrMoA, MnB123H, 42CrMo, 42CrMo4,etc,. For details of the above CHQ Wires, please continue to browse and click on the appropriate grade. If you don't find what you need here, please contact us by phone or email.

Cold Heading Steel

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)